Chiller Plant Optimization with Data Analysis: Unlocking Efficiency and Accuracy

Introduction:

Data Analysis: The Key to Accurate Results:

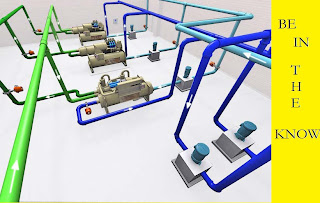

Chiller plants are complex systems that demand a comprehensive understanding of their performance. By harnessing the power of data analysis, we can identify patterns, trends, and anomalies in large datasets, enabling us to make data-driven decisions with confidence. Statistical models such as standard deviation, mean, median, and mode offer valuable insights, shedding light on various aspects of chiller plant operation.

Benefits of Data Analysis:

a) Enhanced Energy Efficiency:

Data analysis allows us to pinpoint inefficiencies and identify areas that can

be optimized for improved energy utilization. By detecting energy wastage

patterns, we can then implement targeted measures to enhance overall system

performance.

b) Predictive Maintenance: By analyzing historical data, we can identify potential equipment failures or malfunctions before they occur. This proactive approach to maintenance helps reduce downtime, increase system reliability, and minimize repair costs.

c) Optimal Load Distribution: Statistical models help us analyze load distribution across the chiller plant, allowing for efficient usage of equipment. By redistributing the load intelligently, we can extend the lifespan of individual units, optimize energy consumption, and reduce operating costs.

d) Performance Evaluation: Data analysis provides an objective assessment of the chiller plant's performance. By comparing actual results to expected values, we can identify deviations and take corrective actions to maintain the system's efficiency at its peak.

Sharing Knowledge and Experiences:

PSIM Makati Chapter

Seminar: Recently, I had the privilege of presenting on this very topic at the

HVAC seminar series organized by the PSIM Makati Chapter. The seminar aimed to

bring together industry professionals to discuss the latest advancements in

chiller plant optimization. The event provided valuable insights into various

approaches, challenges, and best practices of utilizing data analysis for

improved performance. This experience was a great opportunity to exchange

knowledge, learn from fellow engineers, and drive innovation within our field.

To provide some context, the PSIM Makati Chapter seminar was

a four-day event that covered a wide range of HVAC topics. These included HVAC

fundamentals, psychrometry, manual load calculation, software load calculation,

and more. The seminar will culminate (event not done yet at time of posting) with a chiller plant tour on the final day.

One remarkable aspect of the HVAC series was the involvement of an architect

who created a conceptualized hotel building dubbed "MAKATIANS HOTEL" and layout for common floors. This

served as the backdrop for the seminar topics, providing attendees with a

practical context for their learning experiences.

Comments

Post a Comment