CHILLER Efficiencies - Why less is more? From "Habagat-II", Floods, dripping roofs, sweating walls...

During the past few days (August 19-21, 2013) when the Philippines had been battered by torrential monsoon rains that was enhanced by the tropical storm Maring (International name 'Trami') that brought floods to about 60% of the nations capital, I began to think about what would be a good topic to do next for my blog. When the rain stopped and the skies began to be a bit more brighter than the previous days, I went out of our house to check out our surroundings and a man approached me and said that he offers to fix the leaks of our house and whatnot just the same as what he did on the other houses in the neighborhood.

As lucky as me and my family were, to have a home and a neighborhood free of floods; we weren't so blessed to stay in a place that had no dripping ceilings, leaking walls, etc.. Apparently, after I invited him in and we inspected the exterior walls, interior walls, roof and other stuff, the man said that the paint used on the exterior walls of our house is not "waterproof" and that the top most floor of our place which has a kiddie pool and the edges of the firewall does not have waterproofing on and that's why the interior walls were "sweating". Unfortunately, when the house was being constructed, the main theme was to do "tipid" moves and choose whatever the lowest cost materials would be such as using indoor paint for the exterior walls.

So that's it, I got an idea for my next blog post:

Thus, I would like to start this whole thing off about why less is more since the concept of "tipid" sometimes lead to more expenses just the same as the paint on the wall.

WHY LESS IS MORE?? - CHILLERS

When talking about chiller efficiency, I guess everyone who's part of the Industry will agree with me that the main or most popular measurement is Kilowatt per Ton (kW/ton). Just to explain to those who don't know, it's a measurement of how much energy is required to produce a "ton of refrigeration". It's a ratio of how much you put in versus how much you get out of it.

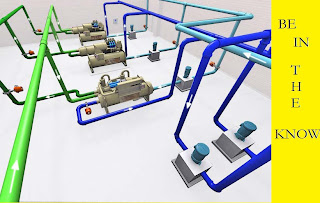

For all you visual people, here's a picture for you:

There are other efficiency measurements out there such as EER, SEER, COP, ILPV, etc. but lets deal with what's being used Here in the Philippines on chillers for now.

Naturally, sometimes, only those that have access to "prime" information could set forth onto the design of their buildings HVAC/R system "prime" design. Unfortunately, we all know the saying "knowledge is power" and an untold consequence to this is that knowledge has a price. Thus, inevitably, because the Philippine model on education is far outdated to begin with and that only a few have access to the right information; then, majority of the people involved in the system:

- Don't take this into consideration

- Fails to look at the things that matter most and focus on something else

- Just cares about the cost

- Is not part of the design and selection of chillers so why care?

To prove this point, if you are a mechanical engineering student or a mechanical engineer practicing

HVAC /R and you don't know by heart the details of this question, then the above serves to be true statements:

- Do you know what ASHRAE standard 90.1-2010 is?

Now, for the benefit of those who are not part of the HVAC field and is just a wandering reader, then let me explain what this is:

ASHRAE (American Society of Heating, Refrigeration and Air-conditioning Engineers) is a non profit technical organization that started way back in the 1800's by engineers in the US and this organization publishes technical standards for buildings and HVAC/R in general.

ASHRAE Standard 90.1 is one of those standards that ASHRAE publishes and these standards are often referenced in building codes all around the world. This standard specifically, is entitled "Energy Standard for Buildings Except Low-Rise Residential Buildings" and its contents sets minimum energy requirements for the majority (if not all) of the equipment being used in the design and construction of a building among other things.

As told by our professor at Trane headquarters in the US, this standard is the fruit of the efforts to decrease energy consumption by buildings during the time when there was an energy crisis in the US back in the 70's due to the oil embargo. Although this standard is not in the law, it however becomes enforceable when it is referenced to be a "Mandatory" requirement if referenced in building codes.

Though there are various organizations in the country that writes codes and whatnot, it is not legalized and we do not have a uniform energy code that puts mandatory requirements on energy consumption. When we look at history, when the Americans felt the "pain" of the energy crisis, then they became active with it and put this standard on their local codes. Aside from putting the standard in building codes, the government must also be vigilant and prioritize implementation and also there must be penalties and or rewards to those that does not follow it and those that do better respectively.

This I guess is what is needed by the Philippines since Filipinos are indeed a "re-active" race and one common trait we have is that we only do something about the situation when we feel the "hurt" already. In my opinion, an energy crisis in our country is foreseeable since there are no new power plants being constructed but there are a lot of construction for new buildings and whatever now and that there will come a time when the demand for electricity will be greater than the supply. We have already evidence of this with rolling blackouts and whatnot that's happening on the land of our fellow men from the south end of the country.

Moving on, since were on the topic of energy consumption then let us first see how important HVAC/R in a building really is..

First we look at how much money is put into HVAC during the construction of a building and we compare it with the other costs.

Here we see a typical pie chart of what we're talking about and HVAC doesn't seem to be that much right? It's only about 9-10% of the total... So, what's the big deal then? Why am I wasting such time when this is all that there is to talk about... 10% of the total?

Well, there's another side to the story... How about we look at the time when the building is fulfilling its purpose; when it's operational???

Wow! That seems to be a big surprise! Is it that much? OOOOOhhh hell yeah!

Well, what about the chillers? How important is it? Well, industry knowledge will tell you that its about 60% of the total HVAC consumption. So, factoring in the math, let us see what that means...

Uhm.... To calculate, we need to find the area along the curve and use integral calculus... Oh wait, no!

It's just 55% x 60% = 33% - Whoa! HVAC is not rocket science after all....

Anyway, there it is, the chillers in a typical commercial building will consume about 33% of the total!

Ok, so now, what does that mean in PESOS??? So, show me the mooooooneeeey!

Below we calculate the operation cost of a single 1000 ton chiller having an "industry standard" efficiency of 0.64kW/ton using a simple, straight forward formula. We can make this so much more complicated than you could ever possibly imagine...- But lets just keep it simple for now so that we have an indicative measurement.

By using the formula above we got a annual operation cost of about 33M.

But what about if we follow ASHRAE standard 90.1? What would be the operation cost?

How about that? The chiller performing at ASHRAE standard level has a lower energy consumption... Well duh, this is why less is more since kW/ton is inversely proportional then that means that the lower kW/ton will result in an overall lower energy consumption.

Now, I wouldn't spend much thought on investing maybe about PHP 8-12M more at first due to the ASHRAE standard chiller costing more due to the fact that a more efficient chiller has more material costs in it (like copper in the evaporator and condenser to improve efficiency, greater refrigerant charge for increase in heat transfer, larger impellers, larger compressors, high efficiency motors, etc.) because I will save about PHP 4M every year if I choose it right?

For all you folks out there wondering and saying in your heads "well, the calculation is only at full load, what about part load?", read about my other blog post here explaining how chiller/chiller plants unload...

So I guess this concludes this entry for now. I hope you've enjoyed reading. Should you have any questions/clarifications, please email me at coolmoako@gmail.com

Just some trivia for you guys:

In the Philippines, the typical "Chiller Plant" System Efficiency (This includes pumps and cooling towers) is rated at about 0.9kW/ton. In Singapore, the latest energy project, the Singapore's "Environmental Building" is rated at 0.55kW/ton System efficiency... Look at how far behind we are....

For all you environmentalists out there, here's the result from the US EPA website if we choose the chiller that meets ASHRAE standard:

You could do it yourself by clicking the link and putting in 408,800 (since we save 1,120 kW-HR per day) on the query box and choosing kilowatt-hours of electricity.

Just imagine, if you choose the ASHRAE standards based chiller, it's the same as planting and growing 7,396 trees!

Not to mention that the kW hour we put in is just in a year's consumption.....

What if all of the chillers in the Philippines meet this energy standard????And oh, by the way, a 1000 ton machine is good only for about an estimated floor area of 18,000 square metres. Mall of Asia (MOA), according to Wikipedia's list of largest shopping malls in the world, (link below) has a gross floor area of 390,193 square metres..

Wiki List of Largest Malls

What this means is that the mall needs approximately 22 of those 1000 ton machines for it to be cooled! - just to give you an idea of how big of an impact the chiller industry creates...

What then would the impact be for us if we follow the energy standard?

Would we be experiencing this climate change thing?

Would we be suffering the floods?

Think again wise Filipino ... You've been hurt... It's about time, Spread the word!

Very informative article! I am looking to purchase an air cooled chiller and I completely forgot to calculate in the cost of construction. Looks like this will cost more than I imagined. $33 million annually is a lot of money. I might have to save up a bit more before I can afford air cooled chillers.

ReplyDeleteHi Ann! Thanks! Sorry if my reply is kinda late, I've been out and about and busy with some stuff.

DeleteAnyway, sorry for the confusion but its not USD 33 Million but the currency i used is in Philippine peso and would be about $720k USD. Well, goodluck on your chiller purchase. Check out http://www.trane.com/ if ever you're interested in our products.

One of the main problems with air conditioners is dirt and, as such, it's important to ensure yours is clean. Simply turn off power to the air conditioner, and using your garden hose, try to remove as much dirt, seeds, leaves and debris as you possibly can. Do this on a regular basis especially during the cooling season. Emergency AC Repair Toronto

ReplyDeleteHi Leena. I agree with you. A clean air-conditioner is an efficient one indeed.

ReplyDelete